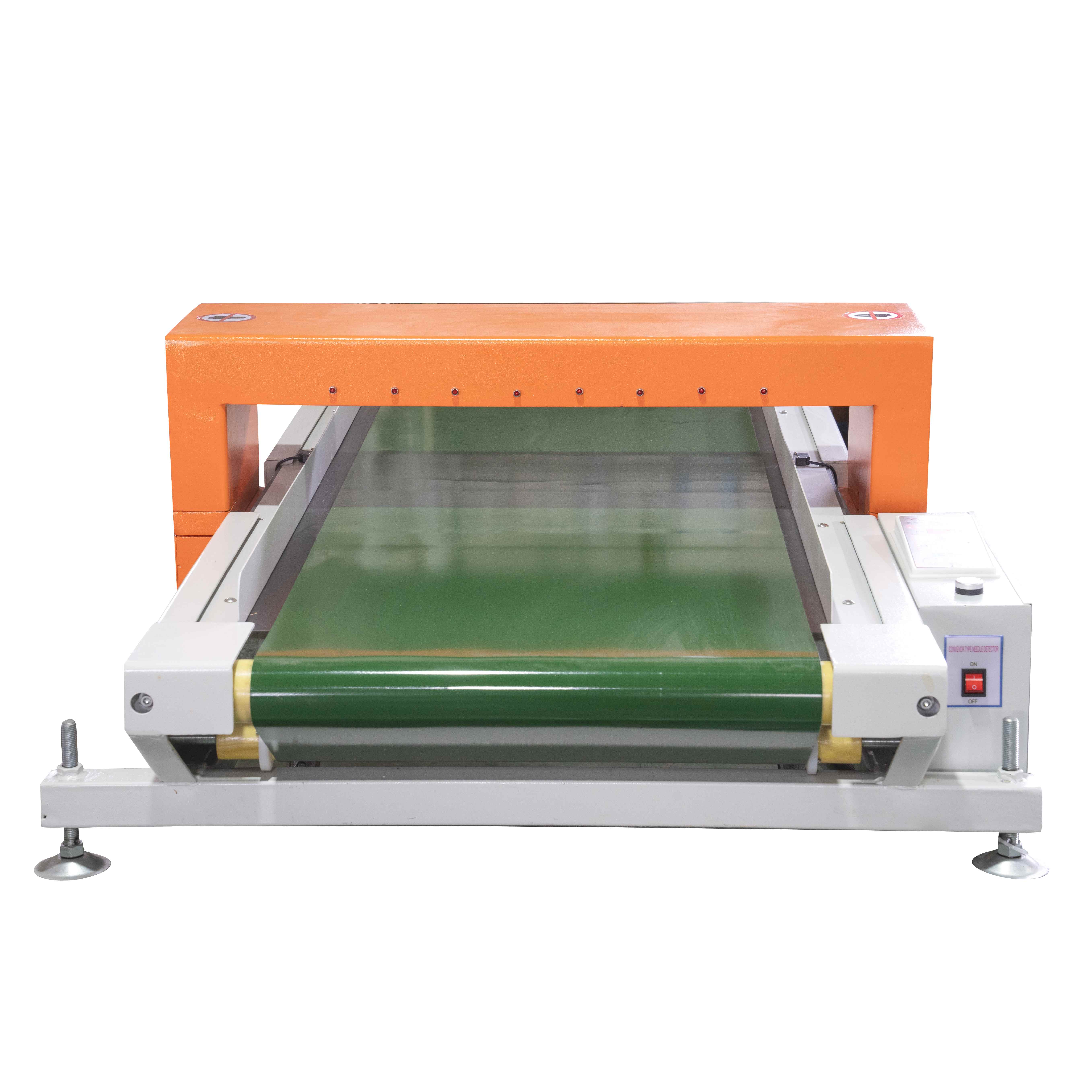

TEXTILE NEEDLE METAL DETECTOR MACHINE

The Needle Detector Machine is an invaluable tool in the textile industry, particularly in the garment manufacturing process. It is designed to detect metal fragments, such as needles, pins, and staples, in fabrics and other materials. This machine is capable of detecting even the smallest metal fragments, and can even identify them by size and shape. The Needle Detector Machine is an effective way to ensure that fabrics are free of metal fragments and that garments are safe to wear.

Additionally, the needle detector can be set up to give an audible and/or visible warning when metal contamination is detected and can be integrated into existing production systems.

It can be applied to various industries, such as apparel, textile, garment, sock, gloves, bedding covers, curtains, shoes, bags, blankets, curtains, nonwoven bags.,etc

Classic Popular Needle Metal Detector Designed for All Forms of needle detection requirement

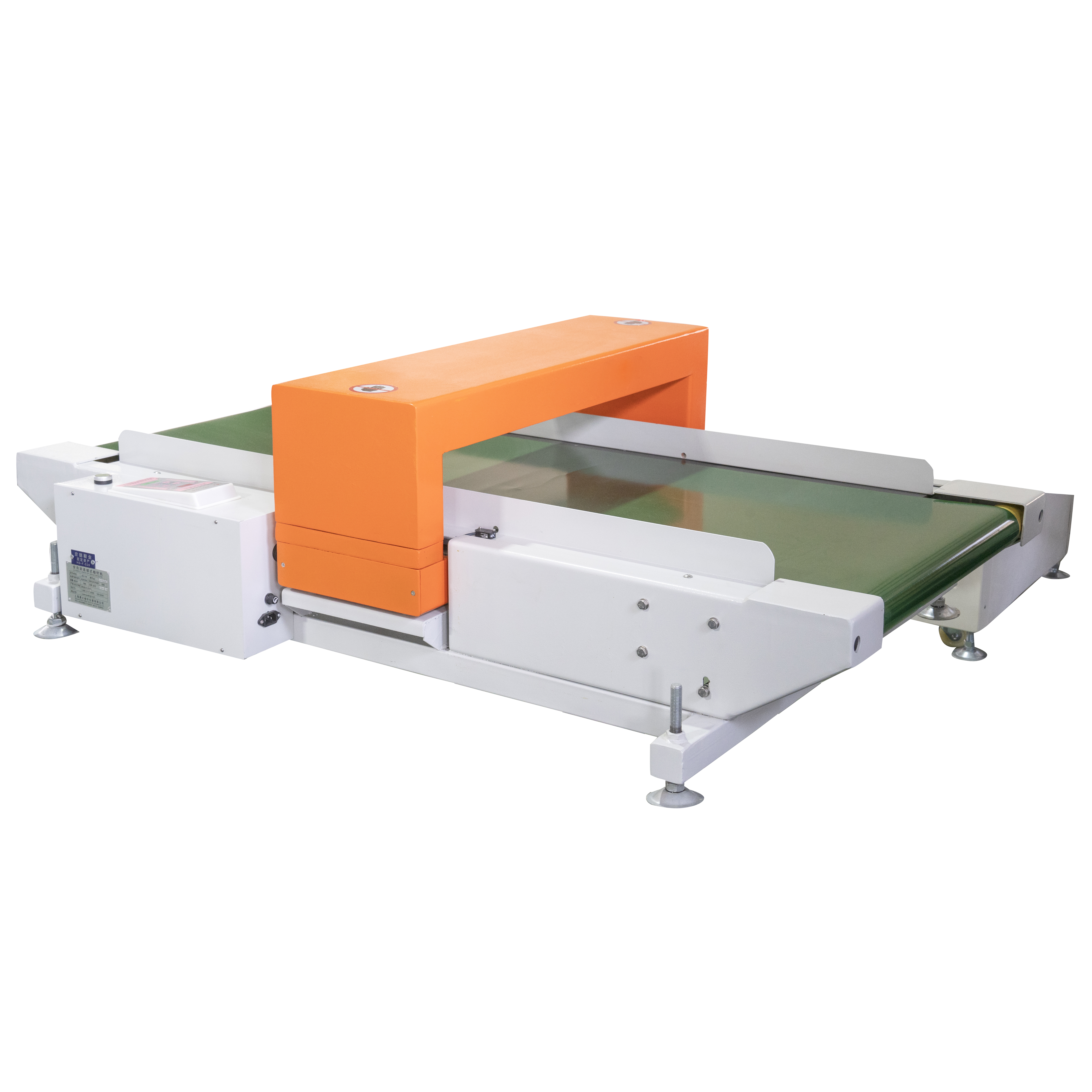

We made various types of needle detectors designed for conveyor belt use, and non-conveyor belt use, suitable for all types of product applications ( with tune-in features). You can choose according to your specific product need.

Reliable, High-Performance Needle Detection

Featuring auto-learn, a great needle-detect sensitivity function can be set up from the system to rapidly deliver excellent metal detection performance out of the box. You can select the product learn from the user interface or for lines with various products switch running test memory.

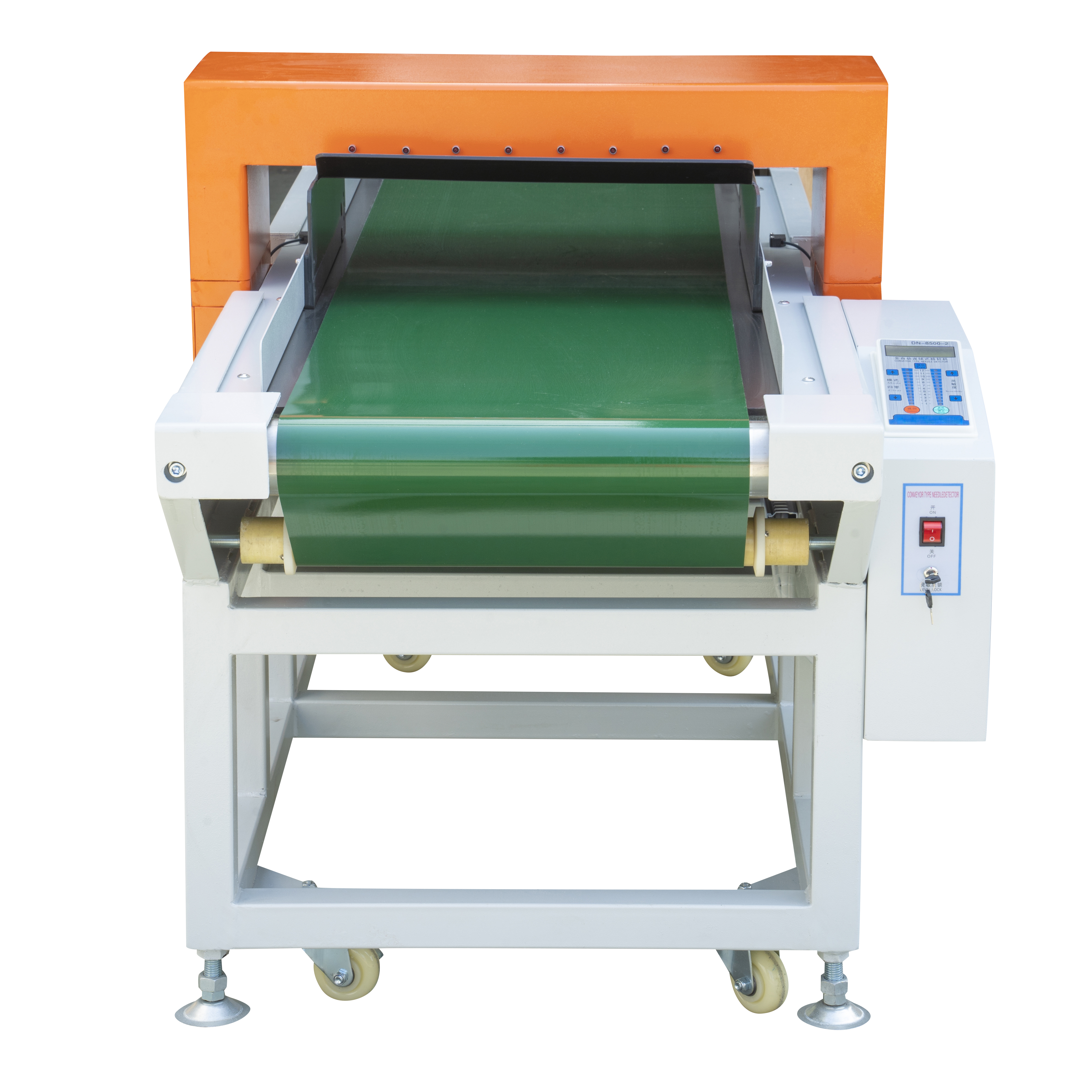

Easy to use, user-friendly interface and operation system

With the simple and clean operation panel with the English Language as default, with the clean and crispy interface, you can learn and use the machine within 5 minutes.

Steady Built to last as a standard

With more than 20 years of combined industry experience, this classic model needle detector is manufactured with years of in-field feedback, building with the best components and precise components. It is easy to clean and combined with ultra-harsh mechanics proven it is one of the toughest and factory user-friendly needle detection machines of all time.\

Specifications

Model: JD-8500 High Sensitivity Needle Detector Machine

Detection method: magnetic field induction, digital circuit processing

Equipment size: 1800*850*950mm

Detection height: 500mm or customized height

Detection width: 150mm or customized width

Detection accuracy: φ0.8mm-2.5mm ferromagnetic metal

Induction adjustment: 1-12 levels adjustable

Alarm mode: sound and light alarm, the conveyor belt stops running or reverses

Power supply: AC220V 50-60Hz

Power: 100W

Drive: 90W/220W/400W motor, gearbox integration

Features:

High Sensitivity Detection Performance

Detect the finest φ0.8mm broken needle/ pin in any textile or nontextile product, ensure quality control 100%.

We make the machine highly sensitive and capable of detecting even the smallest metal fragments. Additionally, the machine’s sensitivity can be adjusted depending on the size and shape of the metal fragment being detected, further increasing the machine’s accuracy and effectiveness.

MODERN & INTUITIVE

Operation Panel in English

A new button control operation panel as standard on every model, a crisp and freshened up interface, and enhanced functionality help deliver a much-improved user experience, helping to minimize user errors and make light work of inspection.

Fully Customization for width, tunnel height

All our needle detectors can be customization fit for your detecting requirement

Faster, Better Auto-Learn:

With significant improvements in signal processing, the new Auto-Learn rapidly delivers excellent detection sensitivities out of the box and provides more line uptime than ever before.

Two intuitive ways to alarm:

1-Stop on Detect conveyors with sound/light alarm:

Stop on Detect (or belt stop alarm) conveyors are the simplest reject conveyor available. They have normally associated with large bulk or awkwardly shaped products that are placed onto the production line by hand and typically consist of head sizes of around 550mm x 300mm. Any product that is contaminated is removed from the line once the alarm goes off and the belt has stopped.

2-Belt Retract with sound/light alarm:

Stop on Detect (or belt stop alarm) conveyors are the simplest reject conveyor available. They have normally associated with large bulk or awkwardly shaped products that are placed onto the production line by hand and typically consist of head sizes of around 550mm x 300mm. Any product that is contaminated is removed from the line once the alarm goes off and the belt has stopped.

Additionally, the needle detector can be set up to give an audible and/or visible warning when metal contamination is detected and can be integrated into existing production systems.

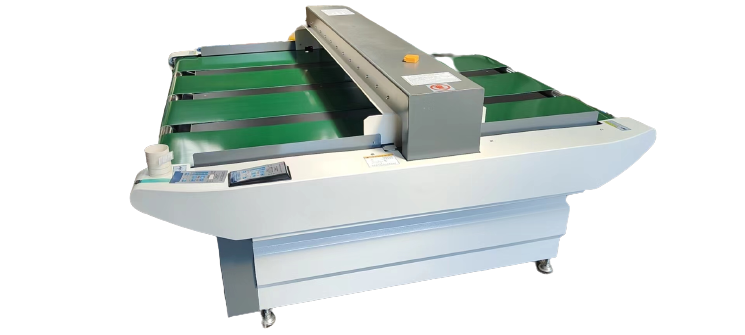

Customized conveyor needle detection systems

We manufacture a broad selection of needle detector conveyor systems for a variety of tailored textile and non-textile product applications. These systems incorporate metal detection technology but also include customized components tailored to specific applications and needs. Additional features may include extra large detecting tunnels for oversized items, incline and decline conveyors, high line heights, dual lane systems, and much more. Contact us today for your tailor-made needle detector machine now!

EXTRA STRONG HIGH SENSITIVITY

Double Heads Needle Detector- Double heads, Double Assurance

Special Design for Shoe needle detection

Production Line inline inspection for shoe, shoes

Extra Wide Width with different conveyor belts

Suitable for extra wide products to improve product capacity

Extra Tall Detecting Tunnel Gate Needle Detection

Suitable big box, carton packaging designs

WARRANTY 2 YEARS

Though most of the machines you saw in the market offering a 1-year warranty, we profoundly offer you 2 years warranty for all our machine models.