Conveyor belt metal detector working principle

by Dongguan Jindu Electronic Technology Co.,Ltd

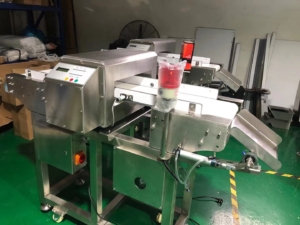

Conveyor belt metal detectors are essential components in various industries, ensuring product safety and quality control by identifying any metal contaminants present in the production line. Their functionality relies on a few key principles.

Principle of Electromagnetic Induction:

Conveyor belt metal detectors operate based on the principle of electromagnetic induction. They consist of a transmitter coil and a receiver coil placed on opposite sides of the conveyor belt. When the transmitter coil emits an electromagnetic field, any metal object passing through this field induces currents in the metal.

Eddy Currents and Disturbances:

As the metal object interrupts the electromagnetic field, it creates what are called eddy currents within the metal. These eddy currents generate their own magnetic fields that disrupt the original field produced by the transmitter coil. The receiver coil detects these disturbances caused by the presence of metal.

Signal Processing and Analysis:

The receiver coil’s signals are then processed by sophisticated electronics within the metal detector. This processing involves filtering out background noise and amplifying the signal from the receiver coil to accurately identify the presence of metal.

Discrimination and Rejection:

Metal detectors are equipped with discrimination capabilities to distinguish between various types of metals. Different metals induce different effects on the electromagnetic field, allowing the detector to differentiate between ferrous and non-ferrous materials. Depending on the settings, the system can ignore certain types of metals or trigger an alarm for others.

Sensitivity Adjustment:

Conveyor belt metal detectors offer adjustable sensitivity levels to cater to different product types and sizes. This feature enables fine-tuning to detect even minute metal contaminants without triggering false alarms due to non-threatening metallic elements or environmental interference.

Alarm and Contaminant Removal:

Upon detecting a metal contaminant, the metal detector triggers an alarm, alerting operators or halting the conveyor belt’s movement. This pause allows for the removal of the contaminated product or the extraction of the metal piece before the production process continues, ensuring product integrity.

Integration with Production Lines:

These detectors seamlessly integrate into production lines, often featuring automatic rejection mechanisms. They can divert contaminated products through side chutes or retracting belts, preventing the contaminated items from proceeding further down the line.

Continuous Monitoring and Quality Assurance:

Conveyor belt metal detectors operate continuously, providing a constant monitoring system to ensure consistent product quality. Regular calibration and maintenance are crucial to guarantee their accuracy and reliability.

In summary, conveyor belt metal detectors employ electromagnetic principles to identify and eliminate metal contaminants in various industrial settings. Their sophisticated technology, sensitivity adjustments, discrimination capabilities, and integration into production lines contribute to maintaining high-quality standards and consumer safety across diverse manufacturing processes.

Looking for a Metal detector machine for your products?

We had it all!

Industrial Food Grade Metal Detector, Garment Textile Needle Detector Machine, Checkweigher Manufacturer in China Since 2012. Your reliable and trusted inspection equipment manufacturer for food & textile industry.

Products

Food Metal Detector

Foil Aluminum Metal Detector

Textile Metal Needle Detector

Checkweigher

Weighing Sorter Machine

SUPPORT

Contact Us

As for a Quote

As for Catalog 2023

FAQs

@ 2023 Jindu Machine Copyright-All Rights Reserved