How does a needle detector work?

by Dongguan Jindu Electronic Technology Co.,Ltd

Needle detectors, also known as metal detection systems or needle inspection machines, serve a vital role in various industries, particularly in textile, food, and pharmaceutical manufacturing. Their primary function is to identify and remove metallic contaminants, such as needles, staples, or small metal fragments, from products before they reach consumers. Here’s a breakdown of how needle detectors work:

Principle of Operation:

Needle detectors operate on similar principles to conveyor belt metal detectors but are specifically designed for detecting smaller metallic objects like needles or metal fragments in products. These detectors typically consist of a search head containing a transmitter coil and a receiver coil.

Electromagnetic Fields and Metal Detection:

When an item containing metal passes through the electromagnetic field generated by the transmitter coil, it induces eddy currents within the metal. These eddy currents disrupt the original electromagnetic field and are detected by the receiver coil.

Signal Processing and Analysis:

The signals received by the receiver coil undergo signal processing and analysis within the detector’s electronic circuitry. The detector amplifies the disrupted signals caused by the metal, distinguishing them from background noise or non-threatening materials.

Sensitivity Adjustment:

Similar to conveyor belt metal detectors, needle detectors offer sensitivity adjustments. These adjustments allow operators to set the detector to varying levels of sensitivity, ensuring efficient detection of even the smallest metallic contaminants while minimizing false alarms.

Alarm and Rejection Mechanisms:

Upon detecting a metal object, the needle detector triggers an alarm, signaling operators to take action. Some needle detectors are equipped with automatic rejection mechanisms, halting the conveyor or activating a mechanism that removes the contaminated product from the production line.

Calibration and Maintenance:

Regular calibration and maintenance are crucial for needle detectors to maintain their accuracy and effectiveness. Proper calibration ensures that the detector operates at the desired sensitivity levels without producing false alarms or missing contaminants.

Integration with Production Lines:

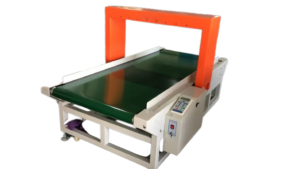

Needle detectors are designed for seamless integration into production lines, often installed in conjunction with conveyor systems. They’re strategically positioned to inspect products as they move along the production line, ensuring comprehensive coverage and maximum efficiency.

Ensuring Product Safety and Compliance:

The primary goal of needle detectors is to enhance product safety by identifying and removing metal contaminants that could pose a risk to consumers. Additionally, these detectors play a significant role in compliance with industry standards and regulations governing product safety.

Continuous Monitoring and Quality Assurance:

Similar to conveyor belt metal detectors, needle detectors provide continuous monitoring to maintain product quality and safety standards. Regular checks and audits of the detection systems are conducted to ensure their reliability and efficiency.

In conclusion, needle detectors operate based on electromagnetic principles, detecting and removing metallic contaminants such as needles or metal fragments from products in various industries. Their sensitivity adjustments, alarm systems, and integration into production lines contribute to safeguarding consumer safety and upholding quality standards. Regular maintenance and calibration are imperative to their effectiveness in identifying and eliminating metal contaminants.

Looking for a needle detector machine for your products?

We had it all!

Needle Detector

( Click for more information)

Industrial Food Grade Metal Detector, Garment Textile Needle Detector Machine, Checkweigher Manufacturer in China Since 2012. Your reliable and trusted inspection equipment manufacturer for food & textile industry.

Products

Food Metal Detector

Foil Aluminum Metal Detector

Textile Metal Needle Detector

Checkweigher

Weighing Sorter Machine

SUPPORT

Contact Us

As for a Quote

As for Catalog 2023

FAQs

@ 2023 Jindu Machine Copyright-All Rights Reserved