Needle Detector Machine for the Textile, Garment, Footwear Industries

Industrial Metal detector machine for the textile industry, inline and offline production lines. To detect broken needle or pin, safeguard your products and your brands.

Conveyor-type needle detector (or non-conveyorized type ) is designed to fit your metal detection requirement in textile,non-textile, garment, fabric, footwear, toy, and carpet. glove, nonwoven fabric industries.

These fully automated broken needle detector machines can detect the smallest pieces of ferrous broken needle/pin in your products. Meet compliance requirements with international standards, protecting your brand reputation.

Needle Detector Machine Introduction

Offer Customization Needle Detector for Your Specific Metal Detection Requirement

We not only design, and manufacture standard needle detector machines, but also offer you customized needle detector fit for your broken needle detection needs. Whether you need a tall tunnel, wide-width conveyor belt, wide-width like 6 meters, in-line installation, extra heavy packaged cartons, or a combination of them all, we can always proudly offer you the customization textile needle detector to your full satisfaction!

High Precision Needle Detector Performance

Optimized needle detector machine in the garment industry, elector-magnetic technology, progressive electronics, and a better, stable anti-interference performance brings maximum protection to your production line and your brands. Even in challenging apparitions, such as a wide width of 6 meters, great sensitivity can be set up and inspected without the need for further optimization.

Robust, Survive on Every Application

With an improved designed control panel and touch screen, proven ultra-harsh mechanics, and full construction in stainless steel our conveyor-type needle detector is easy to clean, maintain, and survive in hard textile & non-textile processing production environments.

Intuitive and Easy to Use Design Concept

A new 7’’ touch screen is available on every model for conveyor needle detector machine, with a crisp and intuitive interface, learn and know how to use it in 5 minutes, helping to deliver a better user experience, while minimizing user errors and making light work of inspection on-site.

Conveyor Type Needle Detector

Jindu’s all-time classic conveyor needle detector machine, high-performance tunnel belt needle detector with an easy-to-use key panel, delivers a great user experience

Model: SND

Operation Panel: LCD Key Panel

Language: English

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: Textile, garment, clothing, baby products, garment accessories, handbags, footwear, fabrics, non-woven, wipes, carpets, gloves, toys, handicrafts, and more

- MODEL

- Specification

- Effective Detect Height

- Sensitivity

- Loading Capacity

- Alarm Mode

- Conveyor Belt Speed

- Control Panel

- Power Supply

- Note

- Appliced to Model SND, X-SND and TW-SND,TP-SND-3

- 6010 6012

- 100mm/ 120mm

- Fe: 0.8mm/0.8mm

- 25KG

- Conveyor Belt Reverse with alarm sound

- Default speed 26 m/min, customized speed available

- LCD Key input control panel as default, touch screen panel available

- 220V 50-60Hz,customized available

- 1. The technical parameter avove namely is the result of sensitivity by detecting only the test sample on the belt, the specific sensitivity would be affected according to the product being detected, working condition and speed.

- Appliced to Model SND, X-SND and TW-SND,TP-SND-3

- 6015 6020 6025

- 150mm/ 200mm/ 250mm

- Fe: 1.0mm/ 1.2mm/1.5mm

- 25 KG

- Conveyor Belt Reverse with alarm sound

- Default speed 26 m/min, customized speed available

- LCD Key input control panel as default, touch screen panel available

- 220V 50-60Hz,customized available

- 2. Requirement for different sizes by customization can be fullfileed.

Needle Detector Machine in Garment Industry

Jindu’s all-time classic apparel needle detector, a high-performance needle detection machine with an easy-to-use key panel, delivers a great user experience, with stainless steel fully constructed, designed to endure and survive for more than 20 years

Model: X-SND

Operation Panel: LCD Key Panel

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: Textile, garment, clothing, baby products, garment accessories, handbags, footwear, fabrics, non-woven, wipes, carpets, gloves, toys, handicrafts, and more

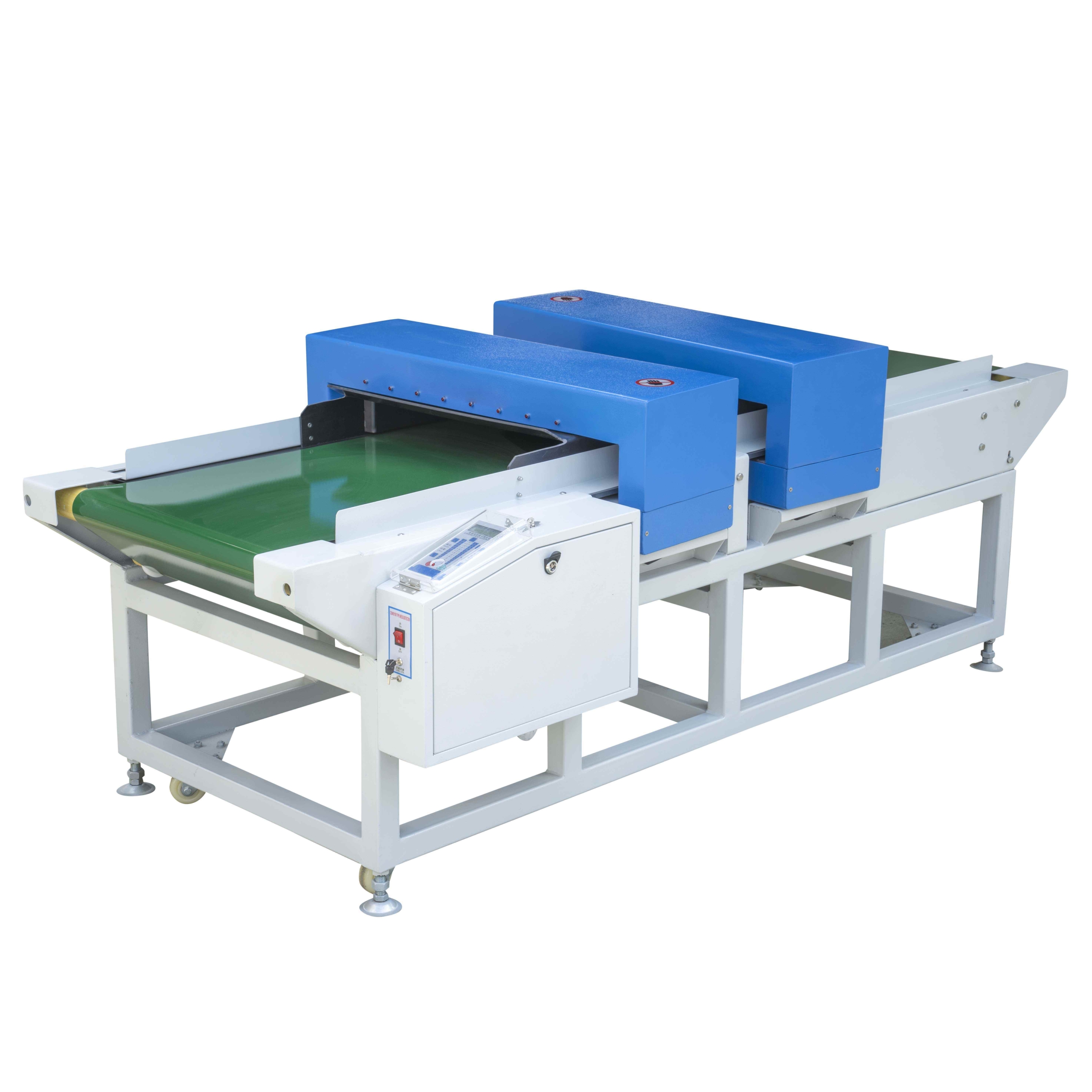

Conveyor Needle Detector Machine- Twin Heads

Jindu’s two tunnels design, double detection for double performance, delivery of maximum detection inspection results

tunnel bear needle detector, a high-performance clothing needle detector with the easy-to-use key panel, delivers a great user experience, with stainless steel fully constructed, designed to endure and survive for more than 20 years

Model: TW-SND

Operation Panel: LCD Key Panel (Touch Screen Panel Available)

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: Textile, garment, clothing, baby products, garment accessories, handbags, footwear, fabrics, non-woven, wipes, carpets, gloves, toys, handicrafts, and more

Needle Detector Machine for Carton Packaging- Tall Tunnel

Jindu’s tall big tunnel conveyor belt needle detector, designed for carton broken needle inspection

Model: C-SND

Operation Panel: LCD Key Panel (Touch Screen Panel Available)

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: For carton, box packaging broken needle detection

Needle Detector Machine for shoe, shoes, footwear, shoe material

Jindu’s needle detector machine design for footwear industry, shoe-making production line

Model: S-SND

Operation Panel: LCD Key Panel

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: For shoe, footwear, and related textile,and non textile footwear production material

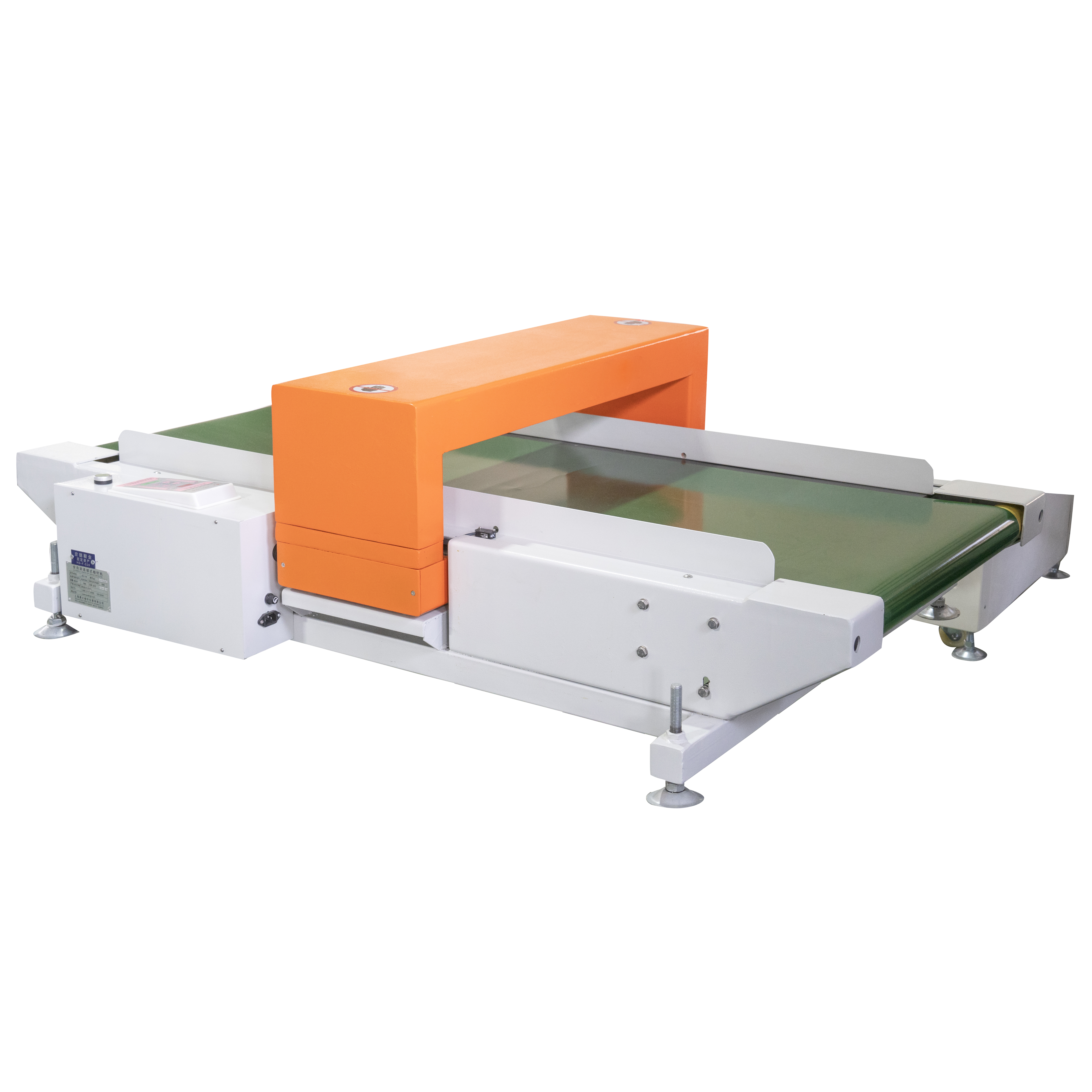

Large Format Needle Detector Machine

Jindu’s tunnel bear needle detector, a high-performance wide width fabric needle detector with an easy-to-use key panel, delivers a great user experience, with stainless steel fully constructed, designed to endure and survive for more than 20 years

Model: LF-SND

Operation Panel: LCD Key Panel

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: Large format Textile, garment, clothing, baby products, garment accessories, handbags, footwear, fabrics, non-woven, wipes, carpets, gloves, toys, handicrafts, and more

- MODEL

- Specification

- Effective Detect Height

- Sensitivity

- Loading Capacity

- Conveyor Belt Speed

- Power Supply

- Note

- LF-ND

- 20010 20012

- 100mm/ 120mm

- Fe 0.8mm/ 1.0mm

- 20Kg

- Default speed 10 m/min, customized speed available

- 220V 50-60Hz,customized available

- 1. The technical parameter avove namely is the result of sensitivity by detecting only the test sample on the belt, the specific sensitivity would be affected according to the product being detected, working condition and speed.

- LF-ND

- 20015 20020 20025

- 150mm/ 200mm/250mm

- Fe 1.2mm/ 1.5mm/ 2.0mm

- 20 Kg

- Default speed 10 m/min, customized speed available

- 220V 50-60Hz,customized available

- 2. Requirement for different sizes by customization can be fullfileed.

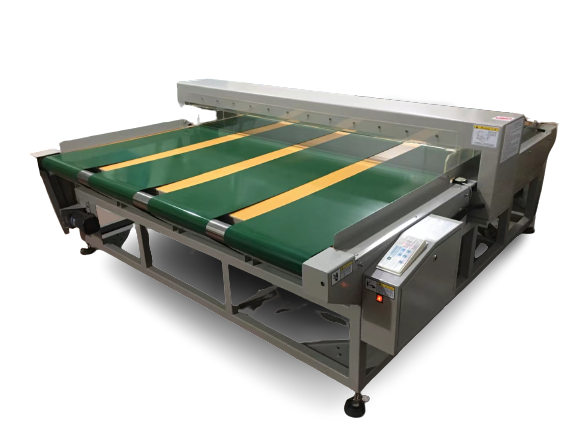

Wide Width Needle Detector Machine Non-Conveyor Belt

Jindu’s wide-width large format fabric needle detector with an easy-to-use key panel, delivers a great user experience, with stainless steel fully constructed, designed to endure and survive for more than 20 years

Model: LF-1-SND

Operation Panel: LCD Key Panel

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: Large format Textile, garment, clothing, fabric, carpet, non-woven fabric, paper roll, foam

- MODEL

- Specification

- Effective Detect Height

- Sensitivity

- Loading Capacity

- Conveyor Belt Speed

- Power Supply

- Note

- Appliced to Model LF-1-ND and LF-2-ND

- 20010 20012

- 100mm/ 120mm

- Fe 0.8mm/ 1.0mm

- 20Kg

- Default speed 10 m/min, customized speed available

- 220V 50-60Hz,customized available

- 1. The technical parameter avove namely is the result of sensitivity by detecting only the test sample on the belt, the specific sensitivity would be affected according to the product being detected, working condition and speed.

- Appliced to Model LF-1-ND and LF-2-ND

- 20015 20020 20025

- 150mm/ 200mm/250mm

- Fe 1.2mm/ 1.5mm/ 2.0mm

- 20 Kg

- Default speed 10 m/min, customized speed available

- 220V 50-60Hz,customized available

- 2. Requirement for different sizes by customization can be fullfileed.

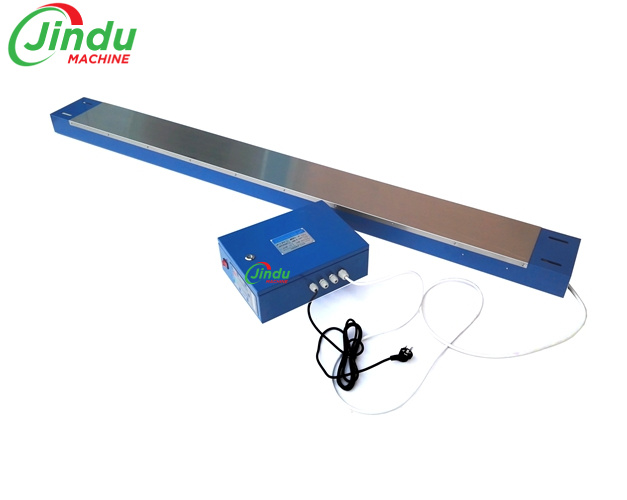

In-inline Wide Width Needle Detector Machine Non-Conveyor Belt

Jindu’s wide-width large format fabric needle detector with an easy-to-use key panel, delivers a great user experience, with stainless steel fully constructed, designed to endure and survive for more than 20 years

Model: LF-2-SND

Operation Panel: LCD Key Panel

Language: English

Machine Material: Stainless Steel 304

Environment Robustness: Suitable for harsh production environment

Product characteristics: Textile and non-textile

Customization: Available

Application: In-line applied to Large format Textile, garment, clothing, fabric, carpet, non-woven fabric, paper roll, foam

APPLICATIONS

Metal detector machine for garment industry can be applied to a variety of industries, such as the textile, garment,fabric, clothing, footwear, apparel, shoe, toy.,etc

In the textile industry, they are used to detect foreign particles such as needles, pins, and metal fasteners in fabrics and clothing.

In the garment industry, they are used to ensure the safety and quality of products before they reach the market.

WHY YOU NEED A NEEDLE METAL DETECTOR?

The primary advantage of using a needle detector machine is its ability to detect even the smallest trace of metal in a material or product. This high level of sensitivity ensures the quality and safety of the product as it is impossible for the human eye to detect metal particles in such minute amounts. Additionally, the needle detector machine offers quick and accurate results, saving time and money. It also reduces the costs associated with potential product recalls and customer complaints due to foreign objects in products.

WHY USE OUR NEEDLE DETECTOR MACHINE?

Quality speaks for everything. We offer the best quality needle detector machine in China, our happy customers keep us going.

AT STOCK

Fast Delivery Time

Delivery

For Standard Machine ( at stock) Lead time: 5 working days

For Standard Machine (not in stock) Lead time: 12 working days

For customized machine lead time: 12 -14 working days

MANUFACTURING PROCEDURES

Food Metal Detector Machine

> FIND OUT MORE

Checkweigher

> FIND OUT MORE

Industrial Food Grade Metal Detector, Garment Textile Needle Detector Machine, Checkweigher Manufacturer in China Since 2012. Your reliable and trusted inspection equipment manufacturer for food & textile industry.

Products

Food Metal Detector

Foil Aluminum Metal Detector

Textile Metal Needle Detector

Checkweigher

Weighing Sorter Machine

SUPPORT

Contact Us

As for a Quote

As for Catalog 2023

FAQs

@ 2023 Jindu Machine Copyright-All Rights Reserved