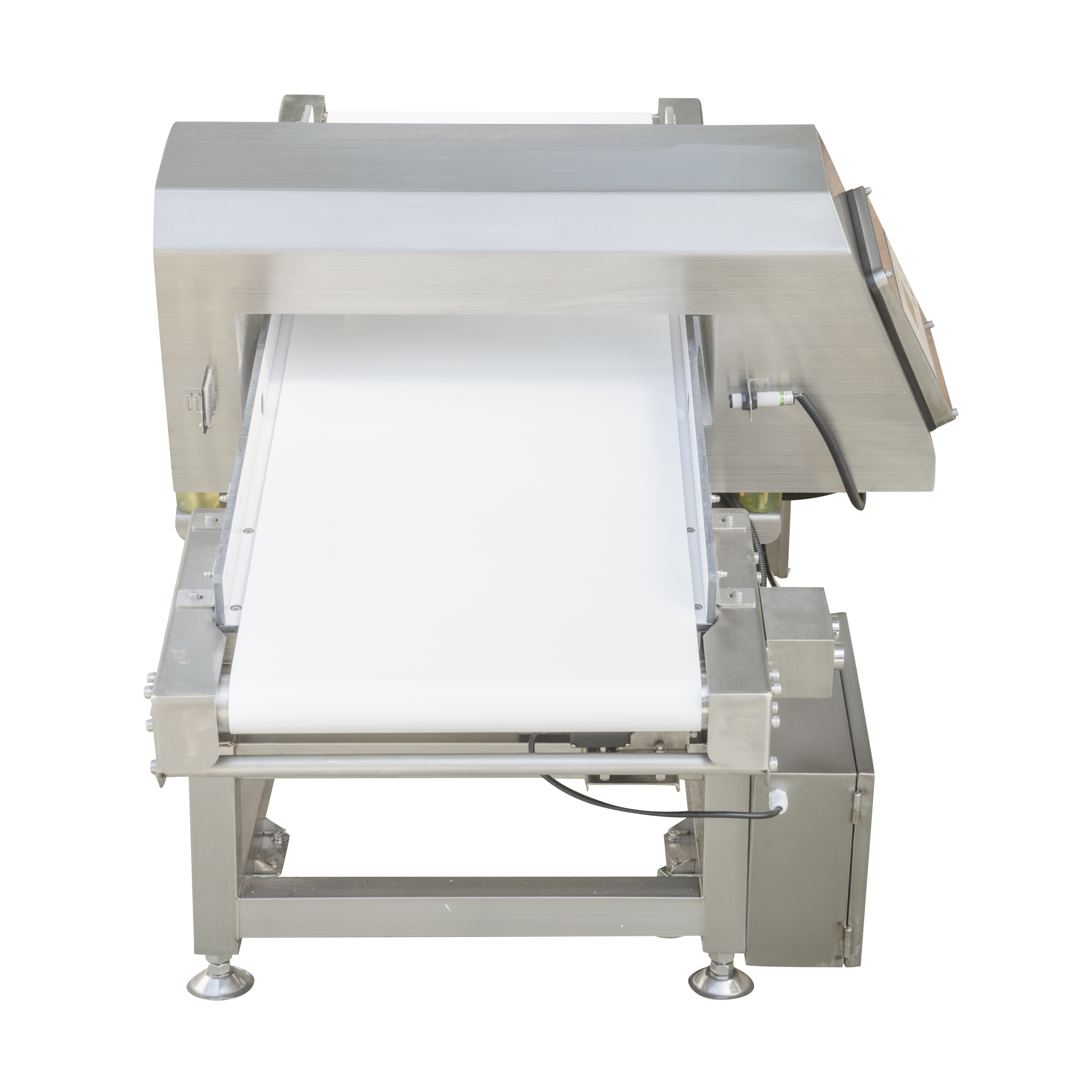

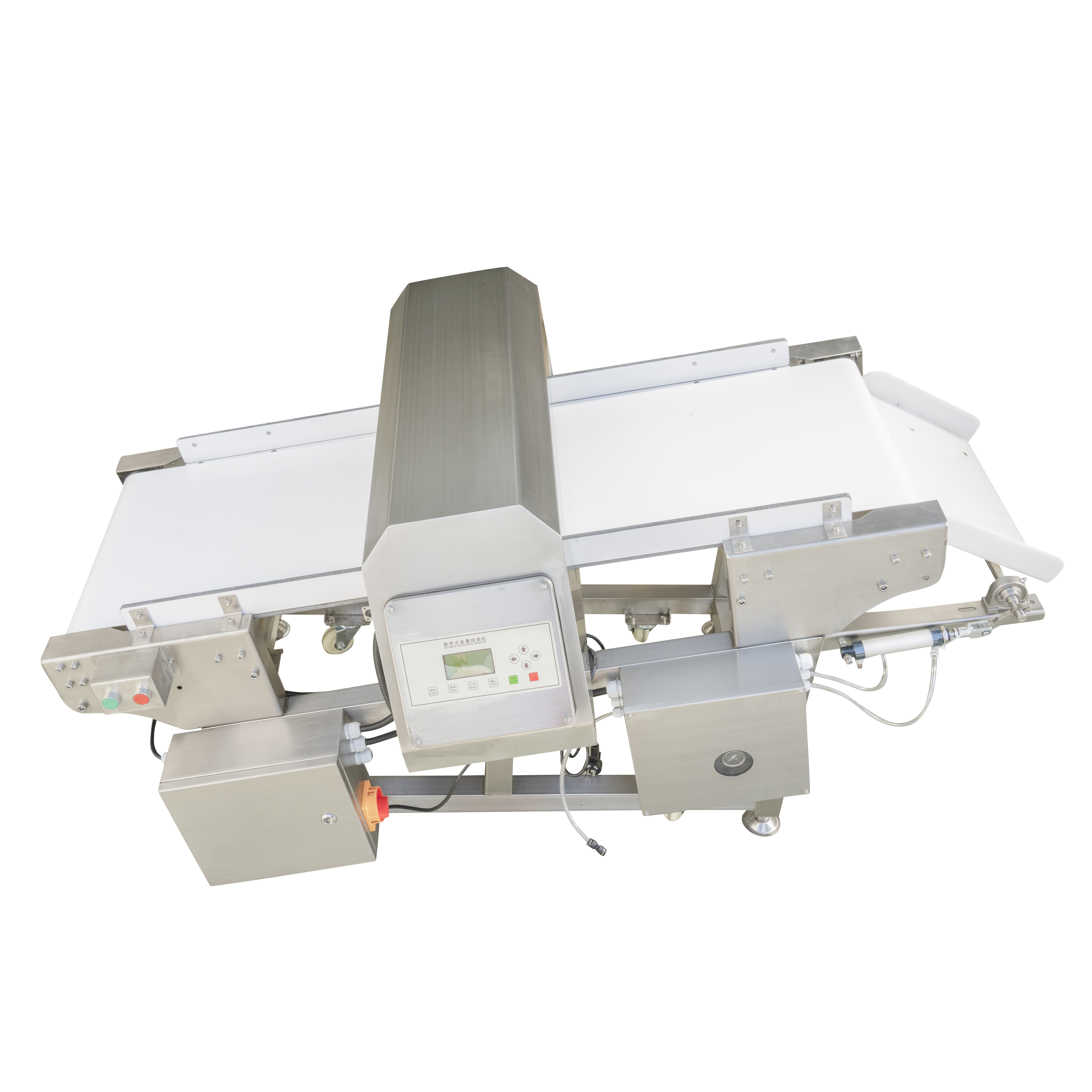

CONVEYORIZED METAL DETECTION SYSTEM MACHINE

Reliable, High-Performance Metal Detection

Featuring auto-learn, great metal detect sensitivity function can be set up from the system to rapidly deliver excellent metal detection performance out of the box. You can select the product learn from the user interface or for lines with various products switch running test memory.

Easy to use, user-friendly interface and operation system

The digital operation panel with the English Language as default, with a clean and crispy interface, you can learn and use the machine within 5 minutes.

Steady Built to last as a standard

With more than 20 years of combined industry experience, this classic model metal detector is manufactured with years of in-field feedback, building with the best components and precise components. It is easy to clean and combined with ultra-harsh mechanics proven it is one of the toughest and factory user-friendly metal detection machines of all time.

Specification

| Description | Automatic Digital Metal Detector with pusher reject device | |||

| Model | MD-JD800 | |||

| Standard | 4008,4010,4012,4015 | 5010,5012,5015,5020 | 6010,6012,6015,6020 | |

| Power Supply | Ac220V 50-60Hz | |||

| Main material | 304 stainless steel | |||

| Detection Width | 400mm | 500mm | 600mm | |

| Detection Height | 80mm,100mm 120mm,150mm | 100mm,120mm 150mm,200mm | 100mm,120mm 150mm,200mm | |

| Detection Sensitivity | Fe | φ0.8mm,φ0.8mm Φ1.0mm,φ1.0mm | φ0.8mm,φ0.8mm Φ1.0mm,φ1.2mm | φ0.8mm,φ0.8mm Φ1.0mm,φ1.2mm |

| Sus | Φ1.5mm,φ2.0mm Φ2.0mm,φ2.0mm | Φ1.5mm,φ2.0mm Φ2.0mm,φ2.5mm | Φ1.5mm,φ2.0mm Φ2.0mm,φ2.5mm | |

| The height from the ground to the conveyor belt | 700mm | |||

| Belt width | 370mm | 470mm | 570mm | |

| conveying capacity | 10KG | 15KG | 20KG | |

| Conveying Direction | from left to right | |||

| Conveyor maximum speed | 30m/min or custom adjustable frequency conversion speed | |||

| Conveyor belt material | Food grade PVC/PU belt | |||

| Display and operation mode | LCD Screen with soft key button input (Optional touch screen) | |||

| Products Storage Quantity | 100 kinds | |||

| Alarm method | Alarm by sound & light, the conveyor belt stops or automatic selection by pusher reject | |||

| Surface Treatment | Brushed stainless steel | |||

| IP grade | IP30(international standard)/ IP54 (optional) | |||

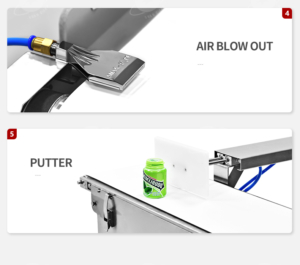

Jindu’s auto-reject types for different products applications

The most common types as below, we can also customize it for your specific demand

-Belt Drop Reject– Ideal for continuous loose products, separate products in parallel lanes across the belt.

-Flip Culling Reject– Ideal for continuous loose products and bag packaging products.

–Bar Removal – The pusher can be located either to the side or above the conveyor for items that have been wrapped in rigid packaging. It can also be built with strong materials. If the product is in a poly bag, it is necessary to place a brush strip beneath the pusher blade to stop it from becoming snagged.

-Air Blow -This system, which is made up of one or two nozzles, is intended to be used on items that are packaged and weigh up to 0.8kg. Suitable for light-packaged objects.

Stop-on Detect (or belt stop alarm) conveyors are the most basic type of reject conveyor. These are often used for large or oddly-shaped items that are manually placed onto the production line and typically have head sizes of around 550mm x 300mm. When an alarm goes off and the belt ceases moving, any contaminated product is taken off the line.

This is an ideal choice for operations that are limited in space since it provides the shortest conveyor lengths.

These systems can also be beneficial for smaller products (by employing smaller aperture heads) that do not require automated rejection, or for food production lines that are not held to a retailer code of practice.

Customized conveyor metal detection systems

We manufacture a broad selection of metal detector conveyor systems for a variety of tailored food and packaging applications. These systems incorporate metal detection technology but also include customized components tailored to specific applications and needs. Additional features may include extra large reject bins for oversized items, incline and decline conveyors, high line heights, dual lane systems, and much more

IP54/IP65 Waterproof Rating

Robust “Designed to LAST LONGTIME” as standard

These metal detector search heads are engineered to endure, with a rating of exceeding IP54 or IP65 for enhanced hygiene, as well as easy cleaning and maintenance. They also boast superior robustness for withstanding any food production environment, no matter how hot, cold, dry, wet, or dusty it may be.

WARRANTY 2 YEARS

Though most of the machines you saw in the market offering 1 year warranty, we profoundly offer you 2 years warranty for all our machines models.

Perfect for these products and MORE!

Meat, poultry and fish

Snack foods & confectionery

Dairy and egg products

Dried foods, cereals and grains

Food-to-go

Fruit, vegetables and nuts

Bakery

Aluminum packaging goods

Extra Features

Various reject alternatives are offered with complete systems,

including pushers, air blasts, carriage retract bands and Stop-on-Detect.

These conveyor systems are made with 304 stainless steel

designed to meet different Retail Codes of Practice.

Specifications

Material: 304 Stainless Steel

Display and operation mode: LED LCD flat key input

Detecting Method: Double Balanced Coil Induction Method

Supply voltage: AC220V 50Hz, single phase 50/60 Hz, neutral & Earth

Power: 100W

Protection Class: IP65

Working environment: -10~50℃,10~90%RH

Alarm method: Metal detected, alarm, conveyor belt stop

Compliance Levels: Stop on Detect (SOD), Auto Rejection,

MORE APPLICATIONS

Air Blow Reject Metal Detector

Pusher Arm Reject Metal Detector

Flap Gate Reject Metal Detector

Roller Receiver Metal Detector

Tall Big Metal Detector

Chain Belt Metal Detector

Belt Down Reject Metal Detector